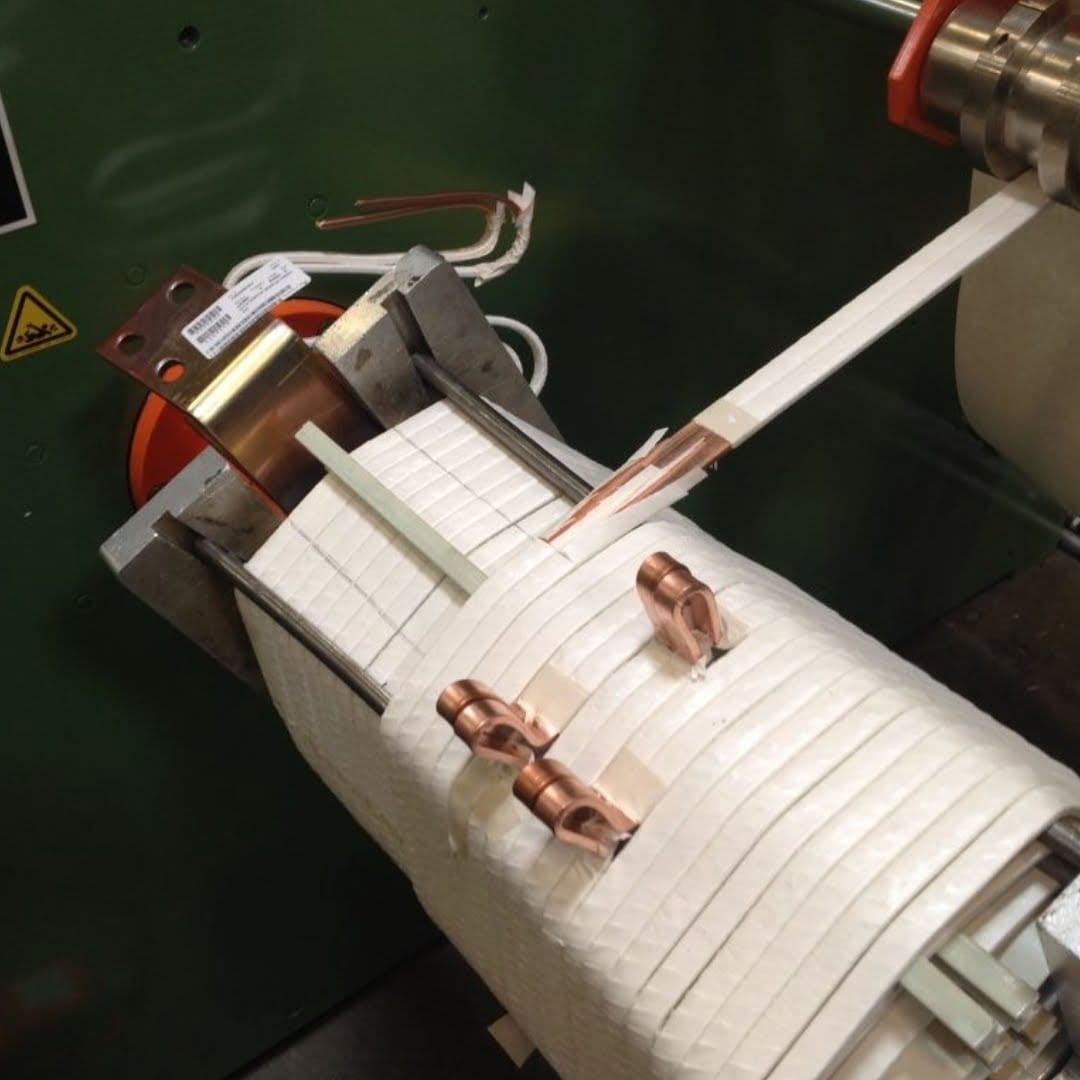

MTM custom manufactures coil winding mandrels for integration with MTM or other OEM coil winding machines.

Round, obround, or rectangular in design, MTM offers a robust, flexible design that will allow for easy integration into existing processes and workflows.

An incremental investment in an expanding mandrel can improve manufacturing capability by up to 40% when compared to fixed form or non-expanding mandrels.

Where Precision Meets Performance

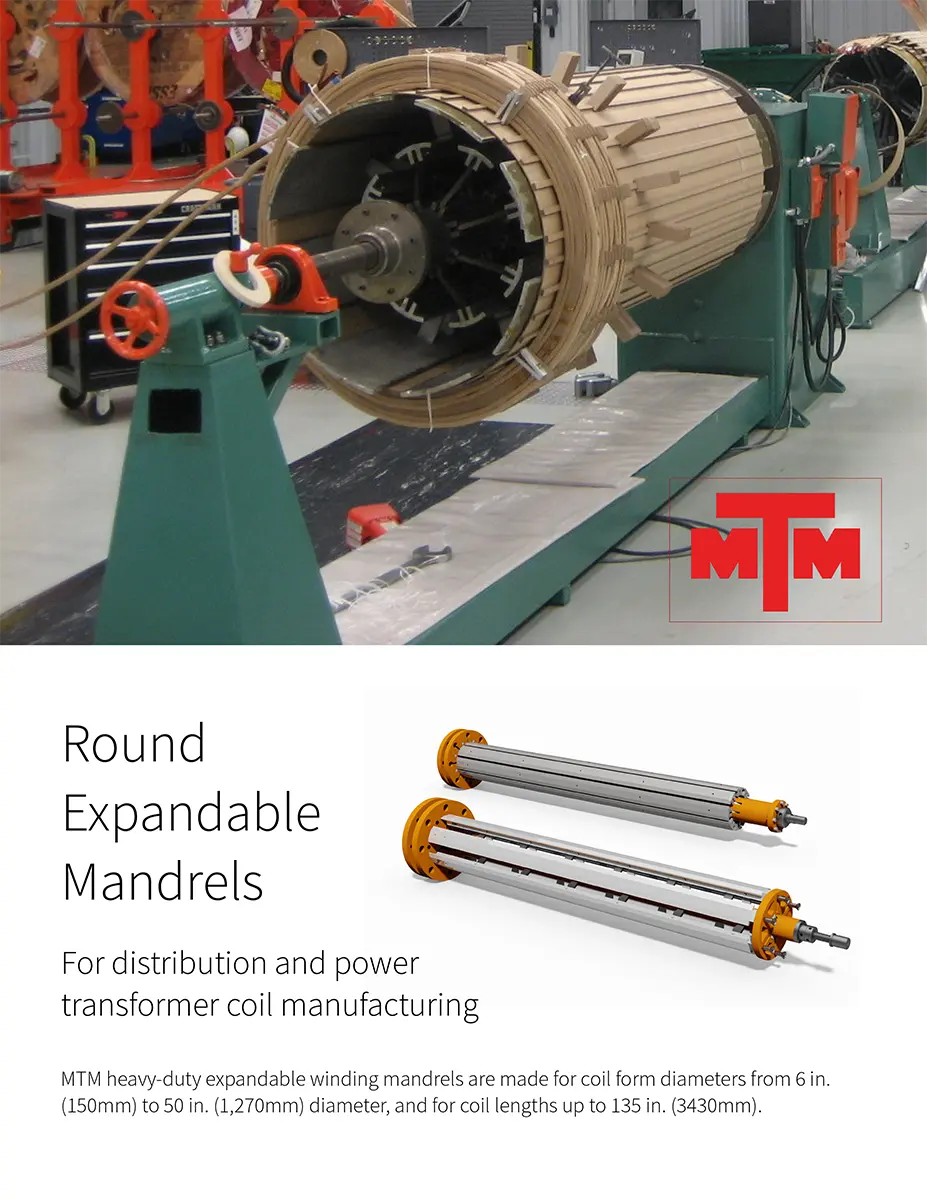

Round Winding Mandrels

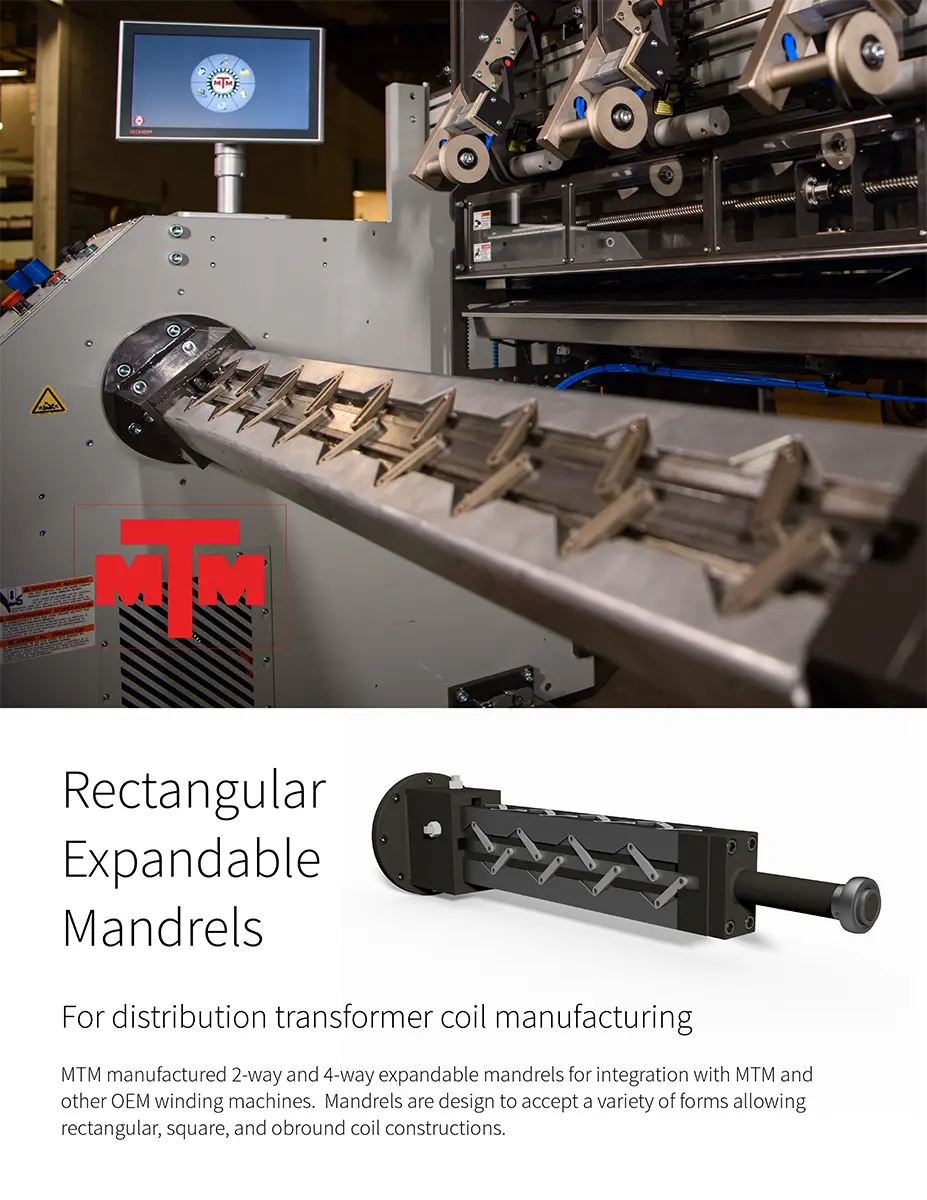

Rectangular Winding Mandrels

Rectangular Winding Mandrels

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

An incremental investment in an expanding mandrel can improve manufacturing capability by up to 40% when compared to fixed form or non-expanding mandrels.

Ready to transform your manufacturing process? Discover how MTM machines deliver quick returns on investment and drive forward the future of transformer production. Why wait to lead the industry?

A lineup of standard machine models that can be customizable to align with your requirements perfectly.

For distribution transformer coil manufacturing

MTM manufactured 2-way and 4-way expandable mandrels for integration with MTM and other OEM winding machines. Mandrels are designed to accept a variety of forms allowing rectangular, square, and obround coil constructions.

Manufactured with a steel structure, the MTM rectangular winding mandrels are designed to provide an infinite adjustment of the outer diameter within the specified range of the mandrel (expanding range typically 1.50 in). The expansion system is designed to support the mandrel under compressive load and will not collapse during winding. Aluminum leaves are designed to accept forms and can be designed to provide a mounting location for the starting busbar.

Suitable for HV and LV coil winding applications, adaptable to any OEM machines

The mandrels are designed to bolt to the winding machine headstock, however, MTM can design custom mounting solutions to meet specific applications.

The mandrel structure is finished in BLACK or ORANGE unless otherwise specified, and parts are nickel or zinc plated where required.

For distribution and power transformer coil manufacturing

MTM heavy-duty expandable winding mandrels are made for coil form diameters from 6 in. (150mm) to 50 in. (1,270mm) diameter, and for coil lengths up to 135 in. (3430mm).

Manufactured with a steel structure, the MTM round winding mandrels are designed to provide an infinite adjustment of the outer diameter within the specified range of the mandrel. The expansion system is designed to support the mandrel under compressive load and will not collapse during winding. Aluminum leaves has a radius on 2 edges providing a support surface and spacing against the inside of the coil over the full diameter range.

Suitable for HV and LV coil winding applications, adaptable to any OEM machines

The mandrels are designed to bolt to the winding machine headstock or to be removed with the coil when the coil winding is complete (depending on the application).

The mandrel structure is finished in BLACK or ORANGE unless otherwise specified, and parts are nickel or zinc plated where required.

Safety

Integrated Safety Systems

A selection of area scanners, light curtains, and physical guards is utilized to ensure the machine is safely isolated from nearby operators. Alignment with local regulations is ensured through close collaboration.

Technology For You

Software, IOT

Machine Operations with Built-In IoT Capabilities

MTM machines offer IoT integration with easy programming, recipe customization, and reliable performance for greater manufacturing efficiency.

Coil Scanning

Machine Operations with Built-In IoT Capabilities

Perform in-process coil measurements with 3D scanning technology to verify that your coils meet specified design tolerances during manufacturing.

Mandrels

Machine Operations with Built-In IoT Capabilities

Round, obround, or rectangular, MTM’s flexible design integrates effortlessly into existing processes and workflows for smooth, efficient operation.

Combination Machine

Revolutionize your coil production with MTM’s versatile wire and foil strip winding machine. A key to a wide range of coil configurations, this advanced, precision technology boosts efficiency and opens new production possibilities.

You May Also Be Interested In

Benders