Machinery Tailored

for Every Coil Need

Rectangular

Round

Oval

Where Precision Meets Performance

Integrated Coil Follower Arm

Tight Coils, Every time…

The Integrated Coil Follower Arm ensures tight coils by applying pressure at the conductor’s corners, shaping the coil. It creates a reverse bend to remove “curvature” or “set,” allowing the conductor to lay flat without excessive tension.

Edge Fill or Stay-back Paper System

Ergonomic Load/Unload, Consistent Operation

The edge fill or stay-back paper system is designed for ground-level loading and unloading, enhancing operator ergonomics. Push-button controls allow easy raising and lowering of the system. Each assembly is easily positioned along the winding machine’s length, simplifying setup between different coil designs.

Edge Fill or Stay-back Paper System

Ergonomic Load/Unload, Consistent Operation

The edge fill or stay-back paper system is designed for ground-level loading and unloading, enhancing operator ergonomics. Push-button controls allow easy raising and lowering of the system. Each assembly is easily positioned along the winding machine’s length, simplifying setup between different coil designs.

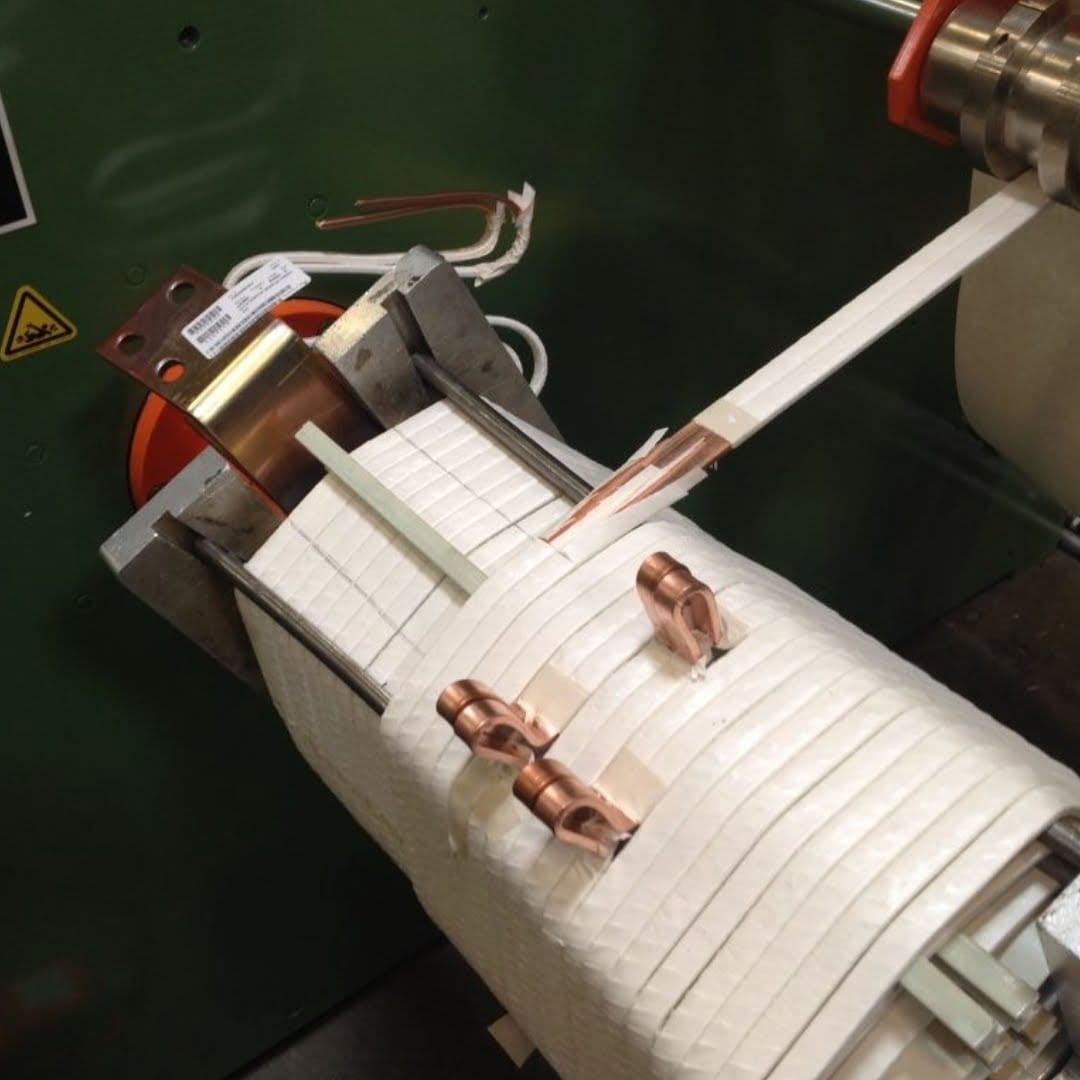

Lead Connections

Cold Welding, TIG, & Laser Welding

MTM provides multiple solutions for lead or busbar connections. Cold Welding, TIG, and Laser Welding each offer distinct advantages to optimize the manufacturing process.

Struggling with inefficiency and high costs? Our CNC-controlled machines are the advanced solution your production line needs.

Ready to transform your manufacturing process? Discover how MTM machines deliver quick returns on investment and drive forward the future of transformer production. Why wait to lead the industry?

A lineup of standard machine models that can be customizable to align with your requirements perfectly.

Safety

Integrated Safety Systems

A selection of area scanners, light curtains, and physical guards is utilized to ensure the machine is safely isolated from nearby operators. Alignment with local regulations is ensured through close collaboration.

Technology For You

Software, IOT

Machine Operations with Built-In IoT Capabilities

MTM machines offer IoT integration with easy programming, recipe customization, and reliable performance for greater manufacturing efficiency.

Coil Scanning

Machine Operations with Built-In IoT Capabilities

Perform in-process coil measurements with 3D scanning technology to verify that your coils meet specified design tolerances during manufacturing.

Mandrels

Machine Operations with Built-In IoT Capabilities

Round, obround, or rectangular, MTM’s flexible design integrates effortlessly into existing processes and workflows for smooth, efficient operation.

Combination Machine

Revolutionize your coil production with MTM’s versatile wire and foil strip winding machine. A key to a wide range of coil configurations, this advanced, precision technology boosts efficiency and opens new production possibilities.

You May Also Be Interested In

Benders